Gas mixer for Chlorine in Argon (Ar/Cl2)

from LT GASETECHNIK:

Both gases, Argon (Ar) and Chlorine (Cl2) are supplied to the LT gas mixer in a gaseous phase. The gaseous chlorine must always be kept at 5°C above the saturation point. In addition, argon must be available with a temperature above 15 °C. LT GASETECHNIK can also heat the gases to the required temperatures at the inlet of the gas mixer.

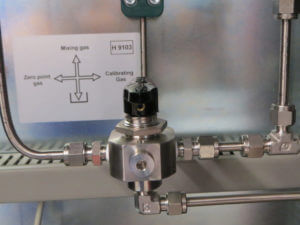

At the entrance to the gas mixer, each gas line has a fine filter. Solid particles that could be dissolved in the gases are reliably retained by these filters.

The argon pressure regulator is made of brass, all other pipes and fittings (mixing chamber, blow-out line for the gas mixture and all connections) are made of stainless steel.

gas mixture

The amount of carrier gas argon and the amount of blending gas chlorine are controlled by MFC (Mass Flow Controller) in order to obtain the desired mixing ratio. A typical mixing ratio is e.g. 5% chlorine in argon.

Typical mixed gas volumes depend on individual customer requirements and vary from 1 to 60 Nm³/h per hour.

The gas mixture pressure can be set manually at the outlet of the gas mixer (e.g. between 3.0 and 4.0 bar).

Control of the mixture concentration

The settings for the desired chlorine concentration in the gas mixture are entered on a touchscreen, which is mounted on the control unit behind a lockable glass door. The mixing ratio is e.g. adjustable from 0.5 to 7.0 vol% (Cl2 in Ar).

On the top of the mechanical part there is an additional cabinet that contains the control and the gas analyzer and is connected to the electrical instruments inside the mechanical part.

The LT Gas Analyzer tests the concentration of Cl2 in Ar and displays this value on the screen. If the measured value deviates from the setpoint, the manipulated values for the mass flow controllers are adjusted accordingly.

This type of control is called cascade ratio control. The design and programming of each gas mixer is proprietary to LT GASETECHNIK:

The amount of gas is determined by the amount of gas withdrawn at the outlet. The carrier gas quantity serves as a proportionality indicator for the cascade-based control of the quantity of additive gas. Each time there is a change in the quantity of carrier gas, the additive gas flow is tracked proportionally.

The gas mixture is continuously analyzed at the gas mixer outlet and the data obtained are used to continuously set the desired concentration. Deviations are used to calculate corrections, which are then applied to the MFC as a correction value.

By controlling the feed gases with a downstream, analysis-guided cascade ratio control, a homogeneous and stable gas mixture is generated.

Further options

In addition, a fully regulated temperature and pressure management can be implemented to ensure absolutely safe starting.

Article as PDF (only available in German): LTG ArCl2-GasMischer