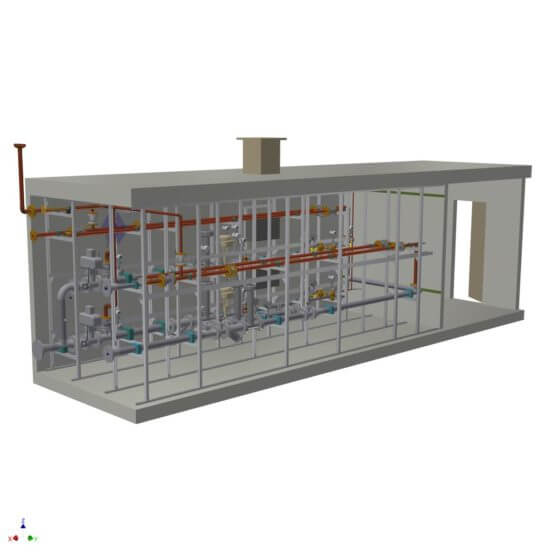

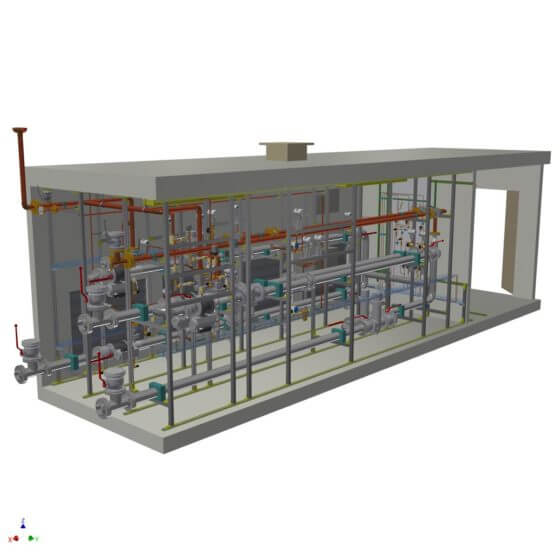

Individually designed gas mixing plants or gas supply plants as control system for pressure and/or volume flow for the glass industry

- Gas mixing plants for supply of burners with defined fuel gases (eg. hydrogen/oxygen mixtures, mixtures with Propane, mixtures with Natural Gas)

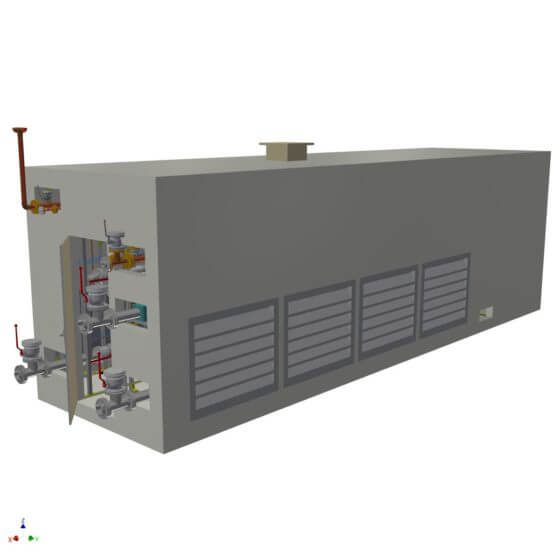

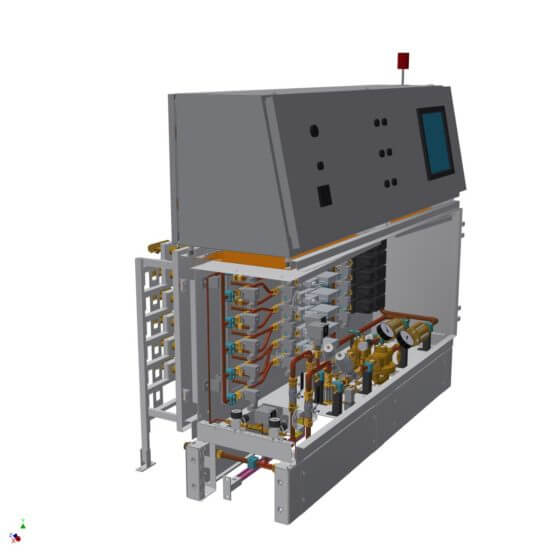

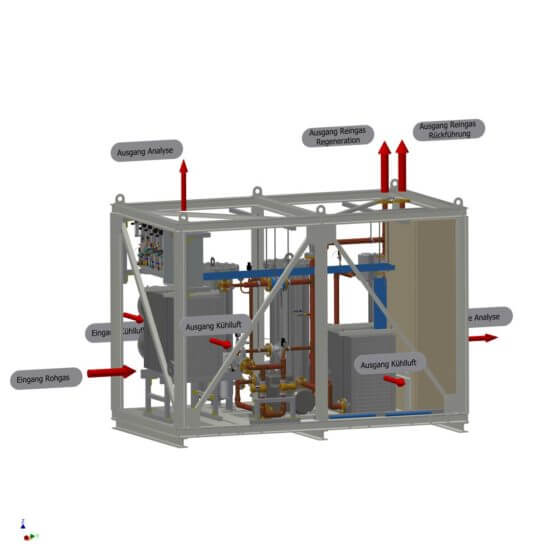

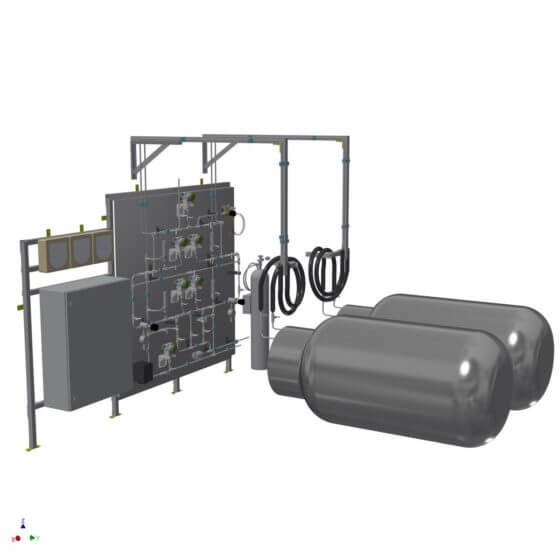

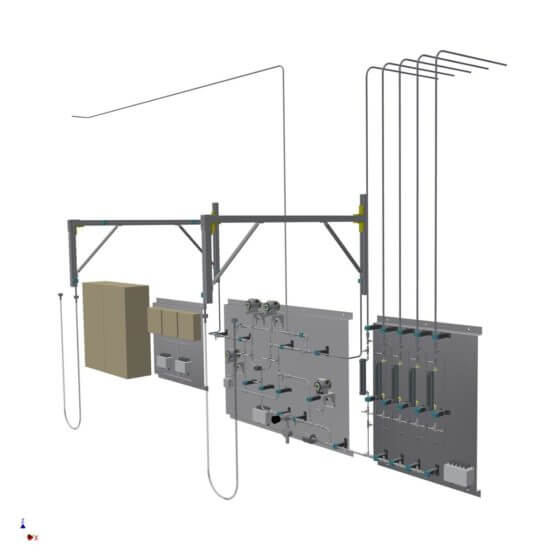

- Gas mixing systems (container or skid) for the generation of protective gas (HNx, HNx-Skid, Bath Atmosphere Mixing System, BAMS, Tin-Bath-Atmosphere-Mixing System, Protective Gas Mixing Station, PGMS) typically for the flat glass / float glass industry)

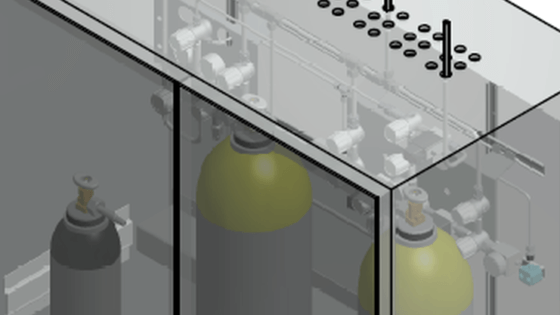

- SO2-supply systems (sulphur dioxide supply)

- Gas mixing plants for mixing Argon with Chlorine (Ar with Cl2)

Gas mixing systems for the float glass industry often have a performance 800-2500 m³ / h per supply line. The equipment can be set up either on a steel frame or in a container. The redundant control system and analysis system for the gas mixture are mounted in a separate area. Process data, alarms and error messages are usually displayed on a local control panel and are transferred to the process control system of the customer.